LASER CUTTING & ENGRAVING FACILITY

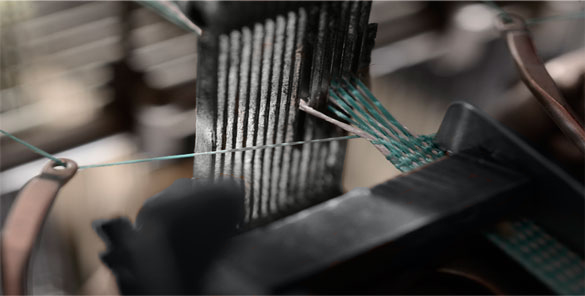

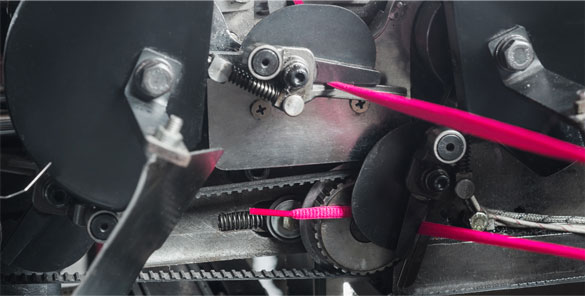

We also have a laser process to complete the whole company. Laser cutting is a machine that uses a laser to cut materials, and is typically used for industrial manufacturing applications. Laser cutting works by directing the output of a high-intensity laser most commonly through optics.

Complete laser process provided for shoes, garment, advertising or other industries. Our processes consist of Laser marking, engraving, and cutting. Material to be processed from leather, fabric, acrylic, paper, metal and many others.